Munkebo

“We produce canned seafood which we ourselves would like to eat. We hope you enjoy it as much as we do.”

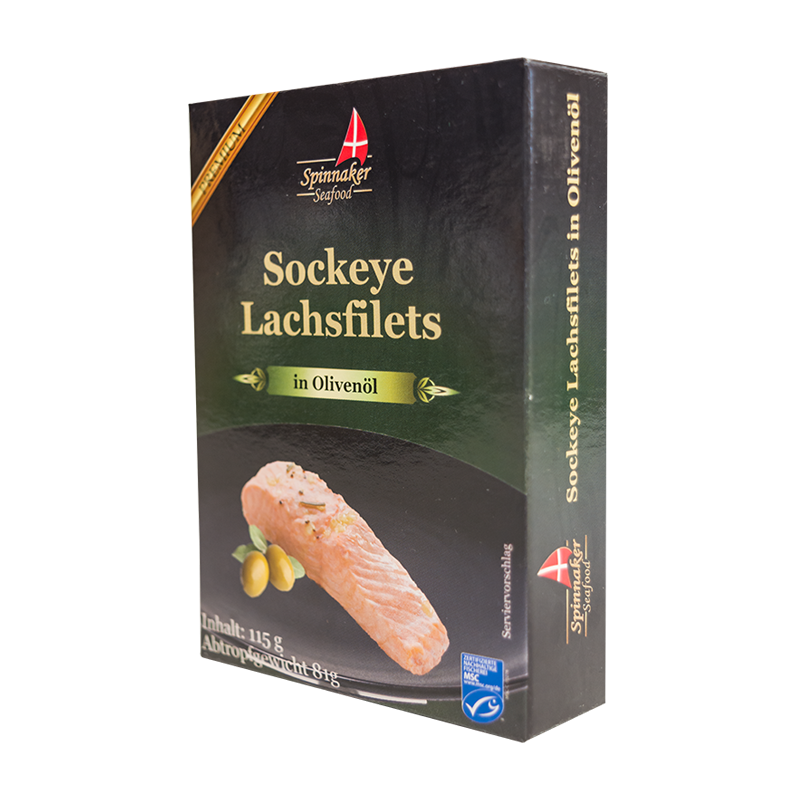

The brand names Spinnaker and The Nordic Soup Pot are owned by Munkebo Seafood A/S.

History

Spinnaker Seafood is a registered brand of the Danish manufacturer Munkebo Seafood A/S.

Munkebo Seafood A/S was established by Hawesta and F. Tengberg Hansen back in 1974. Hawesta was a German can producer and F. Tengberg already had a fish cannery. Therefore, the partnership between the 2 men seemed to be an ideal mixture. Hawesta was looking for a place in Denmark where there was rich access to female labor. Hence Munkebo proved to be the logical place to build the factory because of its neighbour, Odense Steel Shipyard, which employed 5000 men. Munkebo Fine Foods Limited was the name of the company and in the beginning the company mainly supplied Hawesta. The production included herring and cod-liver, but in the early eighties mackerel was also included into the range.

In 1997 the company was taken over by a four-leaf clover with different approaches to the business. The name was changed to Munkebo Seafood A/S. In 2000 the range was changed to what it is today which includes salmon, herring, mussels and soups.

Today we can proudly say that the factory stands as a modern cannery with a high productivity.

Vision

Munkebo Seafood A/S wants to be known as a reliable and trustworthy supplier of canned fish products of the finest quality. Daily we work hard to meet our customers demands and meet the growing demand to deliver canned fish of the highest quality and to supply fish to meet the increasing demands for sustainability.

Quality

Quality Control

We work according to the HACCP principles and we are constantly trying to monitor the production. This ensures a critical evaluation of the system’s suitability, completeness and efficiency and identifies any changes needed.

Through our IFS Certification (International Food Standard) we are ensured that we meet the requirements prescribed by the IFS. This helps to ensure that consumers receive products of the highest standard

Our quality manual ensures that employees always know about processes that need to be made. But, more importantly, how they should be implemented so that we can ensure optimal food safety.

The legislation concerning food changes from time to time.

Therefore the management annually examines processes and adjust according to the rules. The management’s annual verification and the results lead to a comprehensive improvement of efficiency and resource needs and revision of policies and goals.

We test each production thoroughly and samples are extracted for a visuel test concerning taste, aroma and texture. In addition we test our products in an oven at 37 C° to ensure that there is no gas formation during the process. Our products are tested min. once a year by an outside research firm who tests the products’ microbiological and nutritional content.

We are in regular contact with our suppliers to ensure that our raw materials and ingredients meet our standards. We compile supplier reports on all our suppliers. When needed we evaluate if our suppliers meet our requirements.

Quality IFS

The demand for food safety grows. Consumers and authorities increasingly demand that the food we all eat must be of high quality and high safety. If problems occur the error source is quickly found and repaired. The requirements are initially aimed primarily at retail, but from there they spread throughout the food chain to food processing industry, primary producers and transporters.

What is the International Food Standard (IFS)? IFS Food is a standard for auditing of establishments processing food or food packages in bulk. IFS Food can only be used where the product is “processed or handled,” or if there is a risk of product contamination during the first pack. IFS was launched to enhance food safety. Regular audits ensure retailers and ultimately the customer that the facilities, rules of hygiene, education and training meet the established requirements for HACCP.

Sustainability

At Munkebo Seafood we believe in the value of preserving and take responsibility as much as we can for the environment.

We are MSC and ASC certified, and support their work to ensure sustainable fishing.

We do our best to support the preservation of fishing stock worldwide.

We think that the aluminum can is an excellent packaging material, as it does not degrade in the recycling process and so it can be recycled many times.

We also use carton/paper packaging and we support the use FSC or recycled carton to preserve forests.

Ecology

We have organic certification, which certifies that our products are made only from strictly controlled raw materials.

Source of informations and images: munkeboseafood.com